The emergence of laser cutters and engravers has opened up a world of possibility for retail and industrial activities, allowing users to complete projects with impressive precision and accuracy. If you are considering investing in a laser cutter and engraver, it is important to become familiar with its many uses and capabilities. In this article, we will explore the various ways in which a laser cutter and engraver can be used, and provide some insight into the process of getting to know your machine.

Learning How to Use the Machine

Finding the Right Settings

Finding the right settings for your laser cutting and engraving machine is essential for successful results with your projects. It can be a bit of a challenge to figure out exactly what settings you need for a specific job, but once you learn some of the basics, like understanding the differences between different materials and their corresponding settings, you can start working with the laser cutter with confidence. Most laser cutting and engraving machines come with software programs that control the settings of the machine.

You input your desired parameters, such as which material you’re cutting or etching onto and the thickness of the material.

Understanding the Software

Understanding the software is key for using a laser cutting and engraving machine. The software is the bridge between the idea in your brain and the physical object created by your machine. It is the interface you will use to design, cut, engrave, and etch.

Etc.

The “Etc.” section of this blog aims to provide a comprehensive breakdown of all the different ways you can use your laser cutter or engraver.

Exploring Different Applications

Home Decor

Laser cutting and engraving machines are great tools for creating unique home decor. Laser cutters can be used to etch intricate designs or shapes into wood, fabric, paper or any other material. They also can be used for creating textured surfaces, by carefully etching patterns into a material that catches the light in interesting ways.

In addition, laser cutters can be used to cut through materials, allowing you to easily create beautiful art pieces such as 3D wall hangings, decorative plaques, and even intricate jewelry.

Crafts

Crafting with a laser cutting and engraving machine can open up a world of intricate and unique possibilities for anyone who’s interested in creating something special. From woodworking, to leatherwork and beyond, using a laser to create intricate designs and patterns is an experience that many craftspeople cherish. For example, laser engravers can be used to create intricate patterns on wood and metal items, as well as to etch words and images into the surface.

Similarly, laser cutters can be used to cut out intricate shapes from wood, metal, acrylic and other materials.

Business Signage

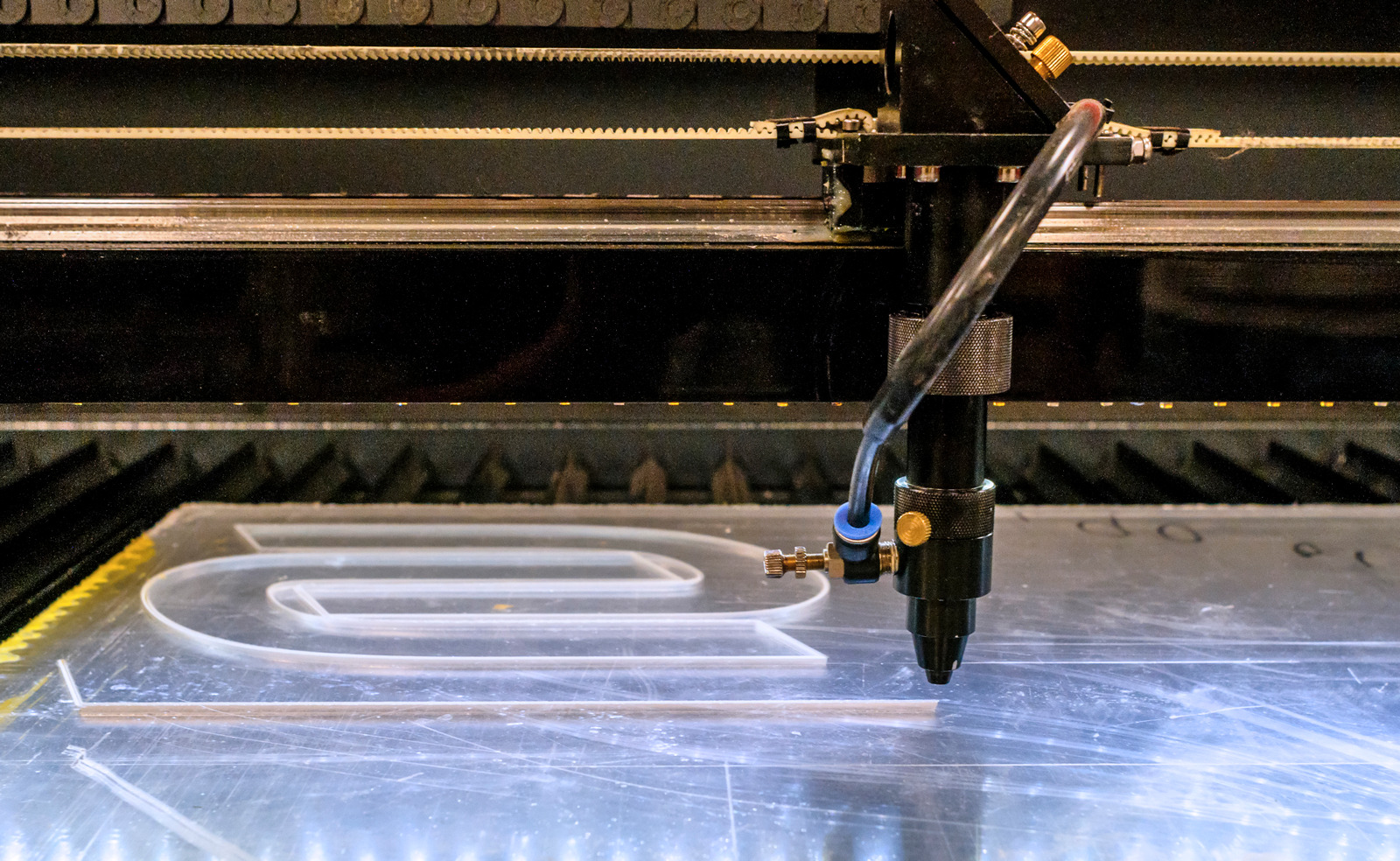

Using a laser cutting and engraving machine for business signage is a fantastic way to make sure that your branding and marketing messages stand out from the competition. Laser etching is well-suited for making decorative elements for signs, logos, and other types of artwork that can be easily cut and engraved on a variety of materials. With a professional-grade laser engraver, you can create intricate, detailed signage that identifies a business, brand and build an eye-catching presence for promoting the visibility of your products and services.

Etc.

The “etc.” section of our exploration into laser cutting and engraving machines can cover many of the other potential applications of these powerful tools. One of these applications is laser etching, which uses a laser beam to create an etch or shallow mark into the surface of an item.

This etch can be used for a variety of purposes, including marking designs, logos, or text, adding decorative patterns and other effects, even cutting into thicker materials such as leather or wood.

Tips & Tricks

Common Mistakes to Avoid

Common Mistakes to Avoid When it comes to laser cutting and engraving machines, there are certain mistakes that should be avoided in order to ensure optimum results. Here are some of the most common mistakes that users tend to make when using their laser cutters and engravers. Not Pre-Testing Your Materials: One of the most common mistakes that people make is not testing their materials before laser cutting and engraving.

Every material’s properties are different and will react differently to the laser cutter’s settings. So it’s a good idea to test out your materials in advance to make sure that it can be cut or engraved properly.

Ways to Speed Up Production

Finding ways to speed up production when working with laser cutting and etching machines can be a game-changer for your business or hobby. There are many tips and tricks out there, whether you are an experienced user or a beginner. The most basic trick is to increase the speed and power of your machine.

Most laser etching machines come with adjustable settings, allowing you to adjust the power of the laser and the speed of the laser beam. By increasing the power or the speed, or both, you can increase the speed of production.

Design Considerations

machine Design Considerations when Using a Laser Cutting and Engraving Machine When using a laser cutting and engraving machine, there are several design considerations to take into account. The laser etching process involves using a powerful beam of light to accurately cut and engrave materials. It is important to consider the type of material you will be cutting or engraving, and its thickness, as different materials require different settings to work effectively.

What you need to know about laser engraving?

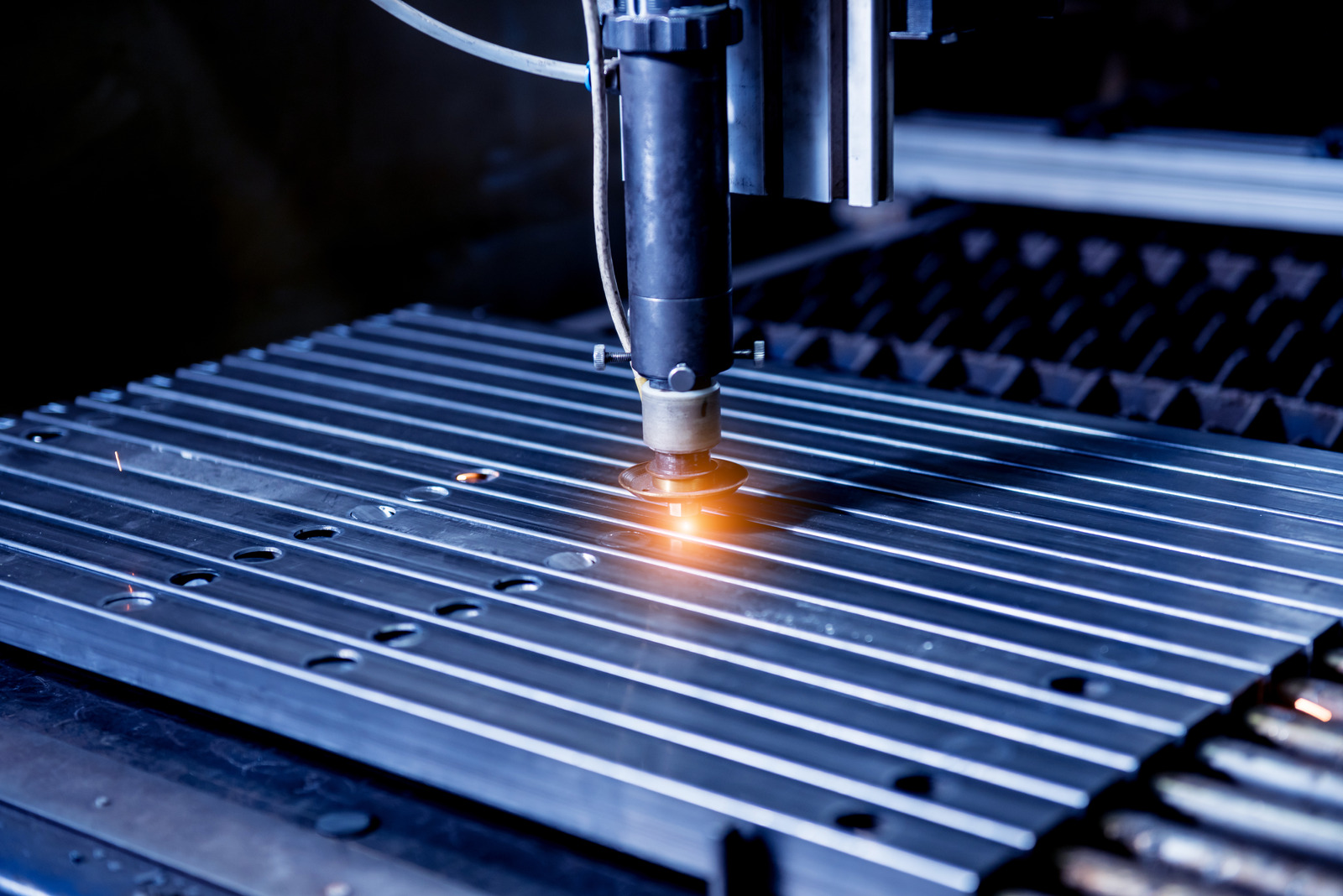

machine If you have been looking into purchasing a laser cutting or laser engraving machine, then you are likely aware of the many different uses they have in today’s world. But what exactly is laser engraving, and what do you need to know to be able to get the most out of your machine? Laser engraving is the process of using precise laser beams to create intricate designs and patterns on either flat or curved surfaces.

This process is used to etch designs into materials such as wood, leather, stone, glass, and metal.

What is laser engraving and cutting machine?

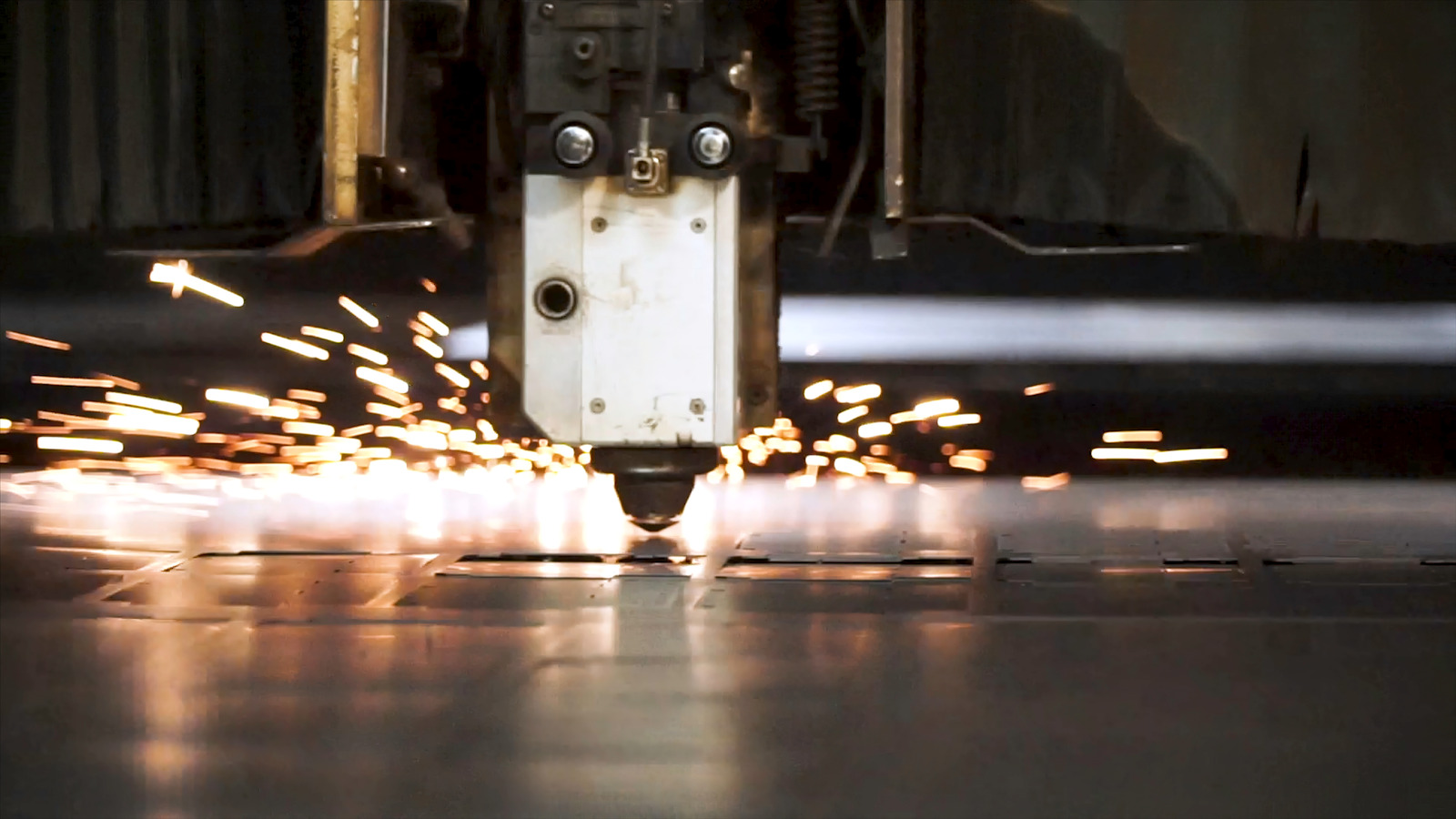

A laser engraving and cutting machine is a versatile machine that uses a laser beam to create intricate shapes and designs on a range of materials. The laser beam is focused and directed at the material, burning away small amounts of material to form shapes and patterns. Laser etching creates shallow cuts while laser engraving creates deeper cuts.

The accuracy and speed of these machines make them very efficient in producing accurate and intricate designs.

What are laser cutting machines used for?

Laser cutting and engraving machines are incredibly versatile pieces of machinery. They have numerous applications across a variety of industries, proving to be incredibly useful to almost any business that puts them to use. Concerning the most popular applications, laser cutting machines are often used in the fabrication of materials such as wood, acrylic, plastic, fabric, and metal.

These machines can be used to cut intricate, complex shapes with high levels of precision. More than just being great for production work, these machines are also popular creative tools, used in the production of customized products and artistic pieces.

Conclusion

Final Thoughts

Conclusion: We’ve come to the end of exploring the wonderful world of laser cutting and engraving machines. This type of powerful, precise equipment is incredibly useful for businesses, artists, and hobbyists alike. With a laser cutter, you can make anything from custom jewelry to personalized awards.

Laser etching allows for intricate and detailed detailing that would be difficult to do by hand. When selecting a laser engraver or laser cutter, make sure you take your time to make sure you find the right one that fits your needs and budget.

Summarizing the Benefits

In conclusion, getting to know your laser cutting and engraving machine can be a great way to open up a new world of possibilities for you. These machines can be used to make engraved art, customized gifts and apparel, as well as intricate signage. They also provide greater precision and accuracy than traditional methods like sawing or hand-engraving.

With so many different applications, laser cutters and engravers are sure to meet most of your needs.

Where to Learn More

Wrapping up our exploration of getting to know your laser cutting and engraving machine, it’s important to understand where you can continue your education and exploration on laser etching. If you’re just getting started with your laser engraver, there are lots of great resources online to help you understand the different parts of your laser cutter and how they work. For those looking to start creating, the internet is a gold mine of laser cutting projects.

From tutorials to iamges, getting ideas for using your laser cutter can be a great way to get inspired and find new ways to incorporate laser cutting into your projects.