The phrase “going beyond the boundaries” is often associated with breaking through barriers, which is exactly what laser cutting and engraving allows us to do. Laser cutting and engraving is an invaluable tool that can make precise cuts with finesse and accuracy. It can be used to add precision to a variety of different products, from making intricate die-cuts to detailed engravings. In this article, we will explore the ways we can push the boundaries of laser cutting and engraving, unlock new possibilities, and create amazing projects.

What is Laser Cutting and Engraving?

Definition of laser cutting and engraving

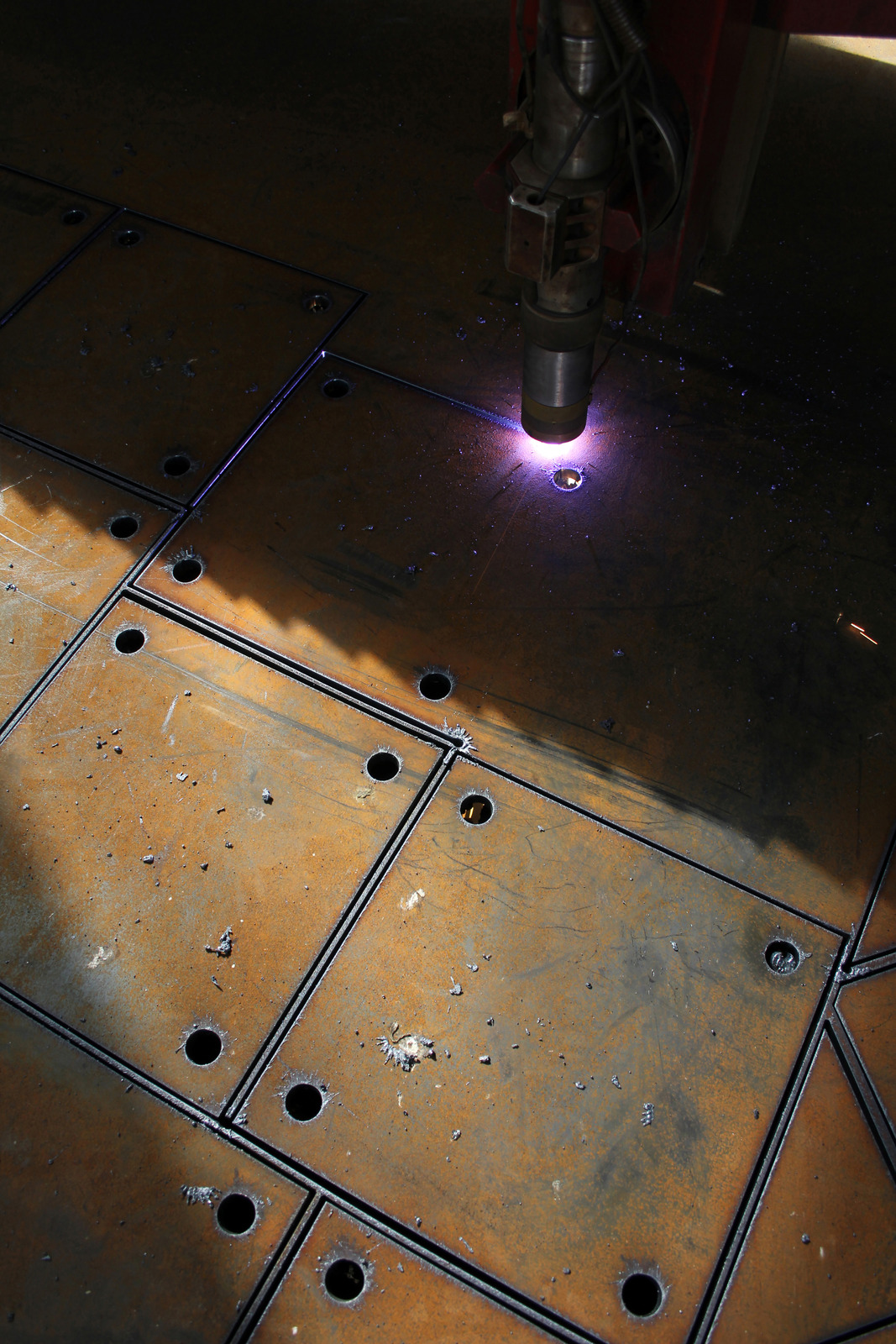

Laser cutting and engraving is a precise technique for cutting or engraving shapes and patterns into materials such as plastic, paper, wood, glass, and metal using a beam of focused light from a CO2 laser source. Laser cutters are a modern alternative to traditional tools such as saws and knives as they offer accuracy, repeatability and computerized control. Laser engravers offer creative control by allowing users to reproduce complex artwork, logos, and text onto a wide variety of materials.

Types of laser cutting systems

When it comes to laser cutting and engraving, there are several different types of systems that can go beyond the boundaries of what can be achieved. The most popular type of laser cutting system is the laser cutter, which is a powerful tool designed to cut, engrave, and mark a variety of materials such as wood, metal, plastic and many others. Laser cutters are generally used in the manufacturing and prototyping processes, but they can also be used for a variety of other projects including creating signs, custom fabrication, and engraving art.

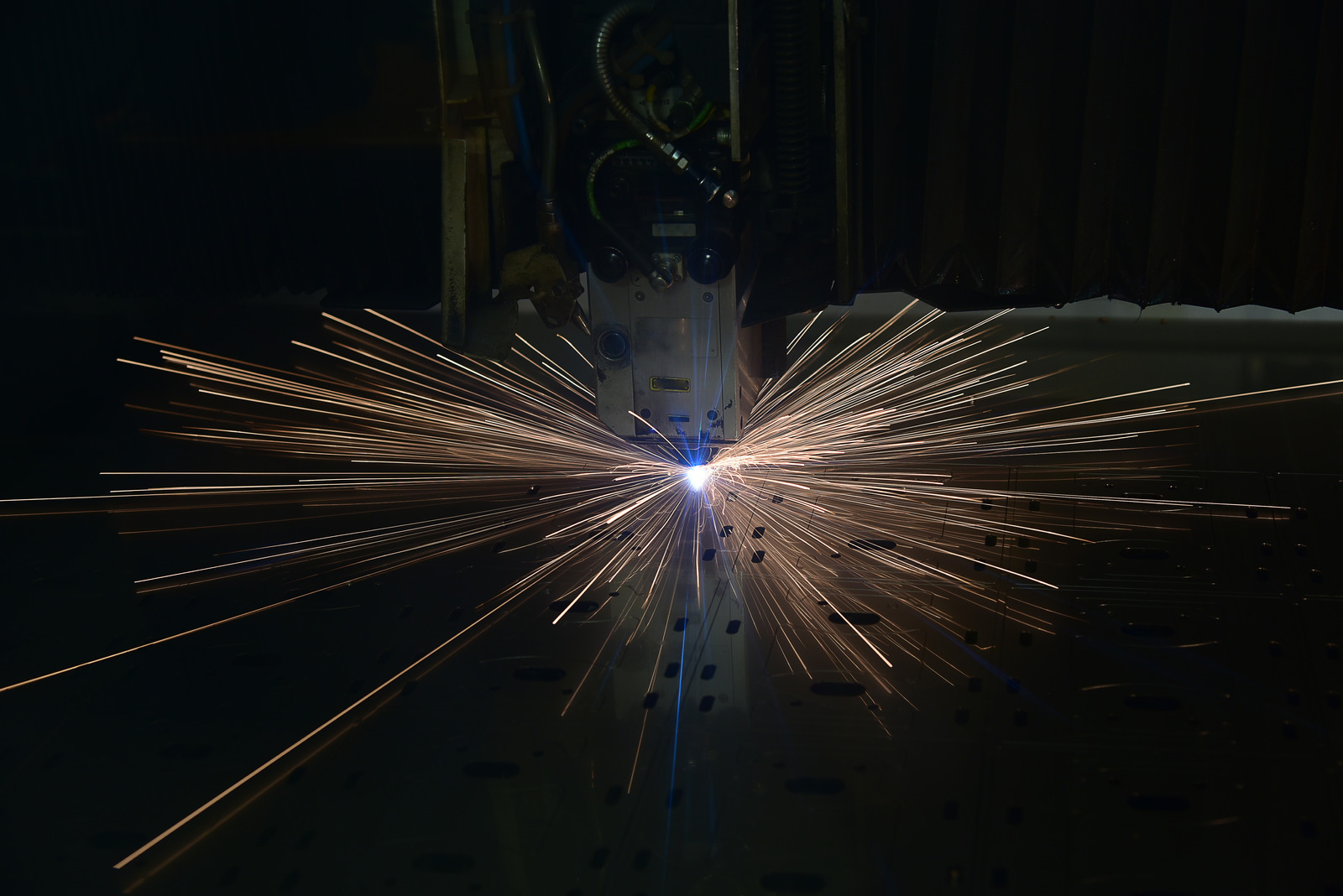

The laser cutter uses a tightly focused beam of light to cut through materials, producing clean and accurate cuts with minimal effort.

Advantages of laser cutting and engraving

Laser cutting and engraving is a popular method of fabricating components from a variety of materials, from plastics to metals. Pre-programmed cutting machines and lasers are used to accurately cut and engrave intricate designs and create complex parts with pinpoint precision and speed. This technology is commonly used in industries such as manufacturing, engineering, and design.

One of the primary advantages of laser cutting and engraving is its accuracy.

Advancing Laser Cutting and Engraving

Different types of materials that can be laser cut and engraved

detail As technology continues to advance, new opportunities for laser cutting and engraving arise every day. With laser cutter technology becoming more accessible and efficient, businesses have the opportunity to go beyond the boundaries of laser cutting and engraving. Innovations in laser cutting and engraving technology have improved flexibility when it comes to the kinds of materials that can be laser-cut and engraved.

The most common type of material that is laser cut and engraved is wood. Laser cutters have become the go-to tool for producing intricate woodworking projects with intricate details.

Laser cutting and engraving in various industries

and engraver Laser technology is no longer limited to just cutting and engraving on materials. There are many diverse industries now using this technology to add a layer of convenience, accuracy, and detail that was not possible with other manufacturing methods. For example, if you are building a prototype for a new product, you can use laser cutters and engravers to precisely cut and engrave the design.

This allows for a higher level of customization and accuracy compared to alternative methods.

Laser engraving techniques

Laser engraving techniques are becoming increasingly popular as more and more people realize the potential of these tools. There are a variety of different laser engraving techniques that are available today, and each one can bring unique capabilities to the table as you try to go beyond the boundaries of laser cutting and engraving. Here are some of the most common techniques used today.

The first technique is laser engraving. This is a process that involves using a high-powered laser beam to burn away the surface of a material. This technique is commonly used to create intricate patterns and designs on a variety of materials, from wood to plastic, and can be used to personalize items like gifts.

Benefits of Going Beyond the Boundaries

Improved precision and accuracy

When it comes to laser cutting and engraving, it’s important to go beyond the boundaries so you can achieve the highest precision and accuracy possible. Laser cutters and engravers are machines that use a laser beam to cut, etch or mark materials with extremely high precision and accuracy. By pushing the limits of laser technology, you can create complex shapes and intricate designs with nearly perfect accuracy.

This not only improves the quality of the final product, but it also streamlines the production process, reducing both labor costs and production time.

Increased productivity

When it comes to cutting and engraving with a laser, the boundaries of what it can do are sometimes considered limited. However, going beyond those boundaries brings a number of advantages that can help to increase productivity, efficiency and effectiveness. One of the first advantages of going beyond the traditional uses of a laser cutter is that it allows for more precise and intricate designs.

Expanded range of applications

When it comes to cutting and engraving, laser cutting and engraving systems are the industry standard. But most people don’t realize that you can literally go beyond the boundaries of laser cutting and engraving. This can be done by expanding the range of applications that laser cutters and engravers can be used for.

The traditional types of laser cutting are typically used for materials such as wood, metal, plastic, and glass.

Summary of going beyond the boundaries of laser cutting and engraving

Laser cutting and engraving is an incredible technology that allows you to create detailed and intricate designs with extreme precision. Using laser cutting and engraving, you can create beautiful works of art, lace designs, furniture, and much more. However, many people remain unaware of the many possibilities that lasers offer beyond this.

Going beyond the boundaries of traditional laser cutting and engraving can open up a world of possibilities for those who are willing to experiment.

Benefits and advantages of taking laser cutting and engraving to the next level

Laser cutting and engraving is a versatile, cost-effective form of industrial fabrication technology. It can be used to create anything from intricate designs to large-scale prototyping. By taking laser cutting and engraving to the next level, you can expand the boundaries of what is possible for metal, wood, plastic, and other materials.

Is laser engraving a good business?

Starting or investing in a laser engraving business can be a great way to capitalize on a burgeoning industry. Laser engraving has become increasingly popular as a method for creating custom pieces for both personal use and for business purposes. It can also be used in a variety of industries, such as fashion, furniture making, jewelry making and more.

The laser engraving process uses a laser beam to cut and etch designs into various materials. This process can be done on a wide range of materials, including wood, glass, stone, fabric and more.

What are the limitations of laser cutting?

When it comes to the world of laser cutting and engraving, the boundaries of what can be achieved are constantly being pushed and expanded. One of the most obvious limitations of laser cutting and engraving is the size of the laser’s working area. Most laser machines have a work area of around 16″ x 24″ and are limited in their ability to cut and engrave larger items.

This means that for larger projects, the size of the laser needs to be increased or special techniques need to be employed to get the desired result. Another limitation of laser cutting and engraving is the material that can be used in the process.

Conclusion

Conclusion The possibilities for laser cutting and engraving are virtually limitless and can enable creators to go beyond the boundaries of traditional methods of making. With the range of materials that can be used, along with the different shapes, sizes, depths, and colors achievable with the laser, almost any design or idea can be brought to life. Using a laser cutter or engraver not only helps speed up the process but also provides a clean, neat, and precise finish that can be used to confidently present projects professionally.