Welcome to the fascinating world of laser cutting! Laser cutting is an easy-to-learn technique that can be used to cut metal sheets like zinc into desired shapes and sizes. It involves the use of a high-powered laser beam to cut a precise pattern into the metal sheet. In this step-by-step guide, we will walk you through the process of laser cutting zinc sheets to unlock the limitless possibilities of creating intricate and customized metalwork. Let’s get started!

Choosing the Right Sheet of Zinc

Different Zinc Sheet Types

When it comes to laser cutting zinc sheets, it’s important to know the different types of zinc sheet available and choose the right one for your project. Zinc sheets come in a variety of finishes and thicknesses, each of which is suitable for different laser cutting projects. Let’s take a look at the different types of zinc sheet available, and how to choose the right sheet for your needs.

First, it’s important to note that zinc sheets are available in both mill and standard commercial grades.

Pros and Cons of Different Zinc Sheets

Laser cutting sheet metal is a popular way to make intricate art pieces, custom signs, and business logos. If you’re looking to create something out of sheet metal, you’ll have to decide what type of material you’d like to work with. One type that many turn to is zinc sheets; it’s a versatile sprayable material with a variety of benefits.

Before embarking on a project that uses laser cutting with zinc sheets, it’s important to understand the pros and cons of the material.

Preparing the Zinc Sheets

Cleaning the Zinc Sheets

If you’re getting started with laser cutting zinc sheets, it’s important to make sure they are clean beforehand. This step-by-step guide will explain how to clean zinc sheets before using a laser cutter. Firstly, examine the zinc sheets for any remaining debris that may get in the way of the laser beam.

You can do this by simply running a finger across the surface of the sheet or using a cotton cloth wipe. Any foreign material should be carefully removed with a soft brush.

Making Sure the Zinc Sheets Are Assembled Properly

When it comes to laser cutting zinc sheets, making sure the zinc sheets are properly assembled and ready to be cut is extremely important. To properly prepare zinc sheets, the first step is to make sure the sheets are clamped together. Clamping the sheets helps to ensure the sheets will stay together during the cutting process, creating a better result.

It’s important to keep in mind that different types of clamping devices are used when preparing zinc sheets. Generally, the right type of clamping device can be determined by the laser cutting machine.

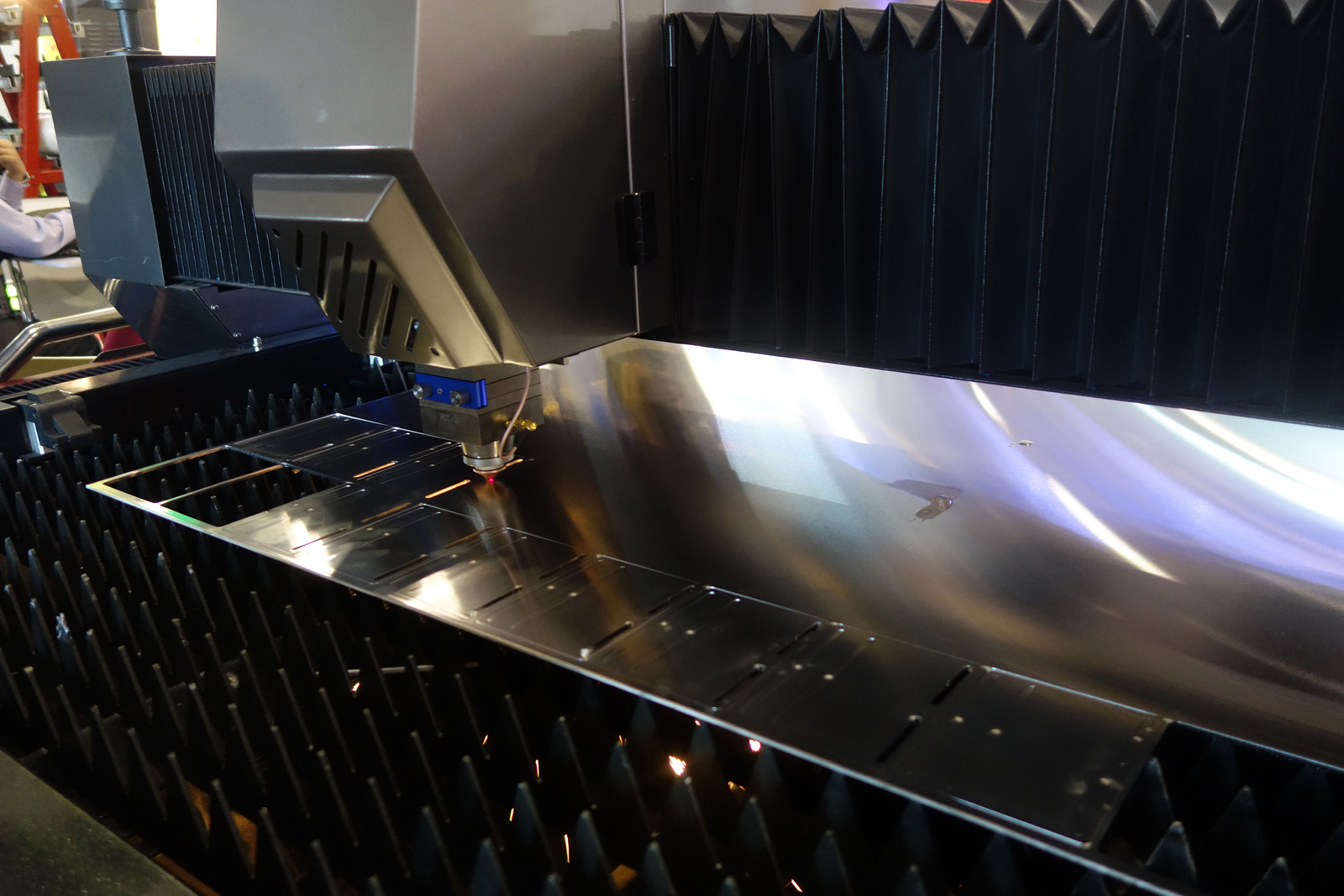

Setting Up the Laser Cutter

Choosing the Right Laser Cutter

When it comes to laser cutting zinc sheets, choosing the right laser cutter is the most important step. Finding the right laser cutter for your specific project requirements is essential for achieving the best possible results and for avoiding unexpected issues. Fortunately, there are a variety of laser cutters on the market today that can handle sheet metal of various thicknesses.

Before purchasing a laser cutter, you should examine the key features of the machine closely. The wattage of the machine, for example, is important.

Establishing the Right Settings for the Laser Cutter

Setting up the laser cutter for sheet metal laser cutting can be a complicated process for beginners, but it is an important step in ensuring that the laser cutting process is successful. Before starting the laser cutting process, you will need to select the proper settings for the laser cutting machine. The most important setting to consider is the power setting of the laser cutter.

Cutting the Zinc Sheets

Positioning the Laser on the Sheet

When it comes to laser cutting zinc sheets, positioning the laser cutter is critical. The laser must be aligned with the sheet metal precisely in order to make a clean cut. Otherwise, the cut will be rough and may ruin the sheet.

Luckily, there are a few tips and tricks to ensure the laser cutter is perfectly placed. First, it’s important to make sure the cutting table is clean and free of debris. This will prevent debris from getting in the way of the laser cutter.

Beginning the Cut Process

Starting the cut process with laser cutting sheet metal can be a daunting task for those with little to no experience. Laser cutters are powerful tools that can quickly and accurately cut through virtually any type of sheet metal, including zinc. To maximize your success and safety, start by preparing the material for the cut, getting your laser cutter set up properly and creating a test cut.

Getting Started: Before you begin the cutting process, you’ll need to prep your sheet metal by making sure it is securely attached to the cutting bed of your laser cutter. Clamps designed for metal are ideal but you can also use double-sided tape.

Finishing the Cut

Removing the Cut Zinc Sheet

Once the laser-cutting of your zinc sheet is complete, it’s time to remove the cut sheet carefully with the appropriate tools and safety equipment. When using a laser cutter, it’s important to take safety precautions in order to protect yourself and your work surface. When handling sheet metal like zinc, you should use protective gloves, eye protection, and long sleeves as you work.

Additionally, be sure you have the necessary tools, such as a pair of vice grips and a hammer, before you start.

Examining the Cut Zinc Sheet

When it comes to laser cutting zinc sheets, examining the finished cut is an essential step that can often be overlooked. After you’ve finished the cut, you’ll want to make sure everything looks right and that all the edges are finished properly. A poorly executed laser cut can result in poor results – and in some cases, you may need to start from scratch.

To check the finished cut, the first thing you’ll want to do is finish off the edges. If you’ve cut a thin sheet of zinc, you may need to use a file to smooth out rough edges.

Conclusion

Advantages of Laser Cutting Zinc Sheets

Conclusion: The advantages of laser cutting zinc sheets are clear–it’s fast and accurate, versatile, and easy to use. Zinc sheets are ideal for laser cutting due to their extremely thin thickness, which makes them easy to cut and shape with a laser cutter. Laser cutting also creates an incredibly clean, precise cut that eliminates the need for additional finishing work.

Tips for Laser Cutting Zinc Sheets

Tips for Laser Cutting Zinc Sheets Laser cutting zinc sheets is a highly specialized process that requires a lot of experience, skill, and attention to detail. The key to success is knowing the tricks and techniques that allow for the best results. Here are some tips for getting the most out of your metal laser cutter when cutting zinc sheets: * Choose the right laser cutter and settings.

Different laser cutters will have different capabilities and settings that can affect the quality of the result.